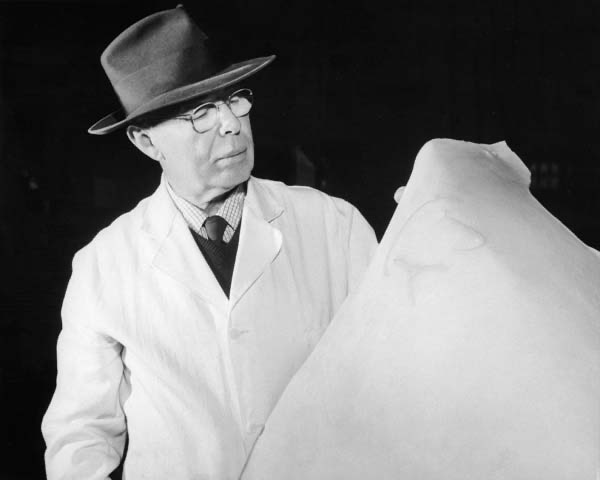

Ansley Kullman Salz holding a sample of the leather made by his company, the A. K. Salz Tannery in Santa Cruz, California. Ansley bought the San Lorenzo Tannery in 1917 with a relative named Herman Kullman and renamed it the Kullman Salz Tannery.

The partnership was dissolved and the Kullman Salz Tannery closed in 1929 due to a failing economy. Ansley Kullman Salz purchased the tannery outright that year and named it the A.K. Salz Tannery. A concert violinist, Ansley thought of leather making as an art form. In so doing, he created the legendary "California Saddle Leather™" which became an industry standard in the 1950’s. A.K. Salz Tannery remained a premier West Coast Tannery until its closure in December, 2001.

Many of the following photographs were taken by Ansel Adams and are the property of the Lezin Family. They are displayed at the Santa Cruz Public Libraries website with the permission of the Lezin Family and the Ansel Adams Trust.

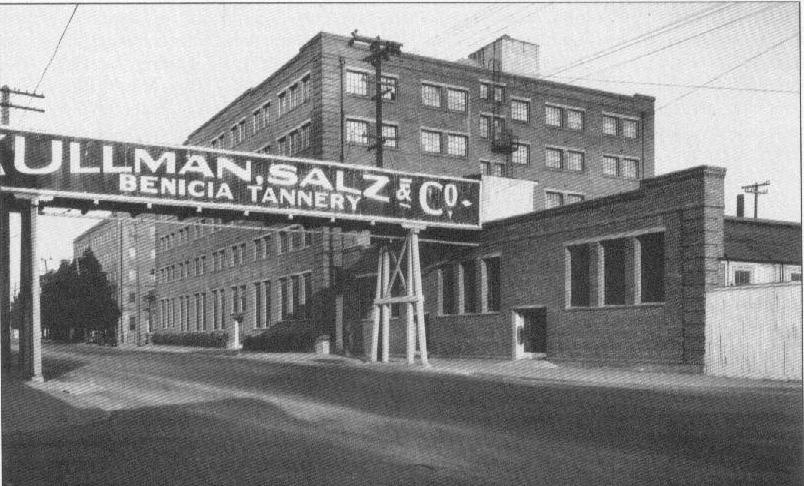

The Ullman Salz Tannery, 1922

The oldest building at Salz was built around 1861, the original "beam house" that housed the wet operations. A horse and wagon used to move bark to the tannery from the drying sheds pauses before crossing River Street/Highway 9.

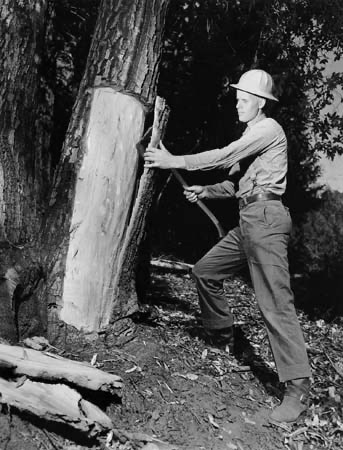

Vester Dick

Green bark was removed from tanoak trees. Salz started harvesting tanoak outside Santa Cruz County in the 1940's and 1950’s, when the local supply dwindled. The Mendocino Coast was deemed the best source at that time. Bark stripping was contract work. The is an employee of a bark harvesting company in the 1950s.

Tanoak bark stacked for drying. Originally harvested locally, tanoak provided the chief ingredient in tanning California Saddle Leather™, a Salz specialty. As local supplies dwindled, Salz purchased it from suppliers throughout California. Salz moved to chrome tanning in the 1960s. By the mid 1980's Salz began purchasing prepared hides and adding finish dyes. Salz ceased the actual tanning process 15 years before the plant closed in 2001.

1955 Ansel Adams

"Papa" Anecito used horse and wagon to transport the tannoak bark from the drying sheds across Highway 9 to the main Salz Tannery buildings. On the very rare days when he was sick and couldn't make it to Salz, other employees had a hard time directing the horse because they didn't speak Portuguese!

Vester Dick

The tanoak used to dye leather was stored in drying sheds across Highway 9 from the main Salz Tannery complex. Modern forklifts replaced horse and wagon in the 1950s. The drying process took about six months. This building was used to store hides that arrived on the short rail spur.

1955 Ansel Adams

Bark storage was crucial to the smooth operation of Salz Tannery. Enough bark to last for a year was necessary. There was no protection from fire at the River Street sheds.

1955 Ansel Adam

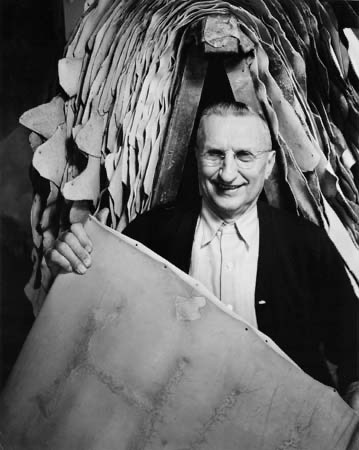

Salz owner and president, Norman Lezin, inspects tanoak bark used to “vegetable"-tan the leather. Tanoak was used as the primary tanning material until the early 1960s. After that leather was tanned using a chrome process.

1955 Vester Dick

Hides were brine-cured and dosed with rock salt at slaughter houses to preserve them in transit. After months soaking in salt pits at the tannery, the hides were stacked and awaited the next process.

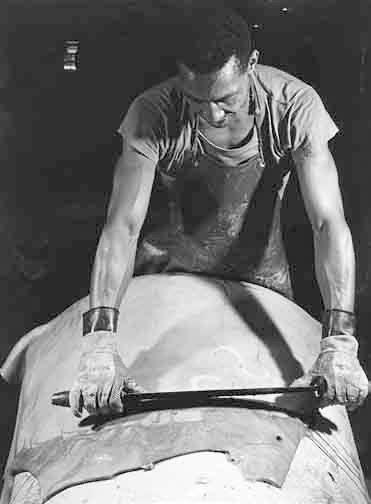

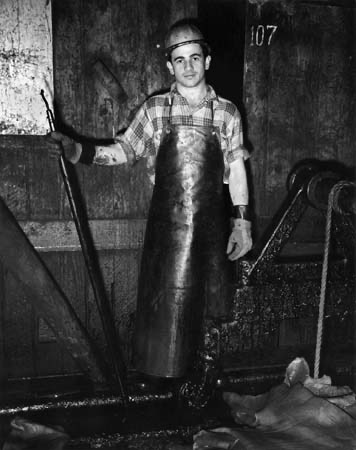

Scudding removed fine hair roots from the hides. After hair and flesh were removed chemically and mechanically, hide were hand-scudded to produce leather of even grain and depth. It was an exacting and challenging task. The implement used was a large, dull blade. The hide was stretched over a wooden, sloped structure designed specifically for this work called a "horse".

1955 Ansel Adams

Ansel Adams photographed this Salz employee wearing a typical beamhouse outfit. The coverings were made of leather for safety because hides were tanned in large open pits.

Tan pits could be dangerous so employees often worked in pairs while removing vegetable-tanned hides from them. Jeremy Lezin remembers that as a kid "Salz sales manager Howard Halper fell into the pits while conducting a tour.” The term "vegetable-tanned" refers to the organic nature of the tanoak bark. It is used to indicate "other than mineral" tannages.

Mid-1950s

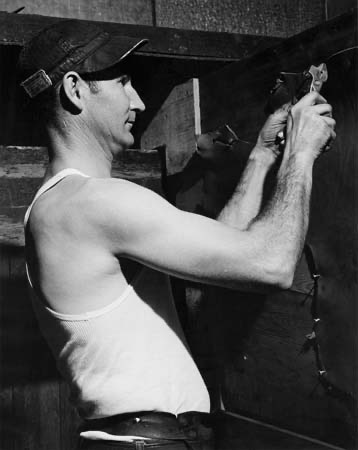

Salz employee Parky Hibbard tacks leather to large boards prior to drying. The hides stayed tacked to the boards for several days before being moved to the next process.

1955 Ansel Adams

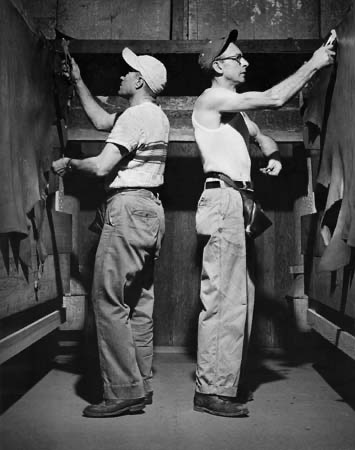

Mel Stubendorff and a co-worker tack the hides up to boards.

1955 Ansel Adams

Vegetable-tanned cowhide, drying slowing in the tack rooms high above the tanyards.

1955 Ansel Adams

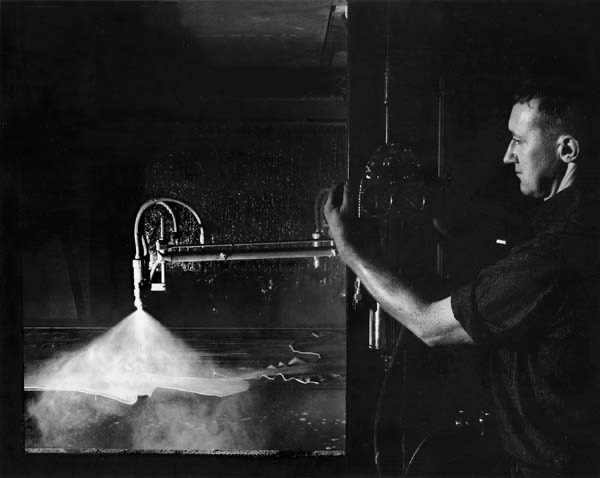

The spray machines at the tannery required constant adjustment. Depending upon the chosen finish, the spray booths deposited waxes, lacquers, oils, dyes, pigments and protein solutions on the dry leather. After this process the leather was plated. In the case of California Saddle Leather™, the glazing jack imparted a brilliant, smooth shine.

1954 Ansel Adams

Glazing Salz's California Saddle Leather™ at a glazing jack. Each side of the hide was glazed twice to create a mirror-like surface. The protein (albumin) used in the glazing process was derived from egg whites. The glazing jack used polished glass to burnish the surface of the leather with heat and pressure. This smoothed the grain or surface and brought up a rich luster. On some leathers this was the final process. On others, like California Latigo™, it took place in the middle of the finishing process. Parafin was used to “ stuff” latigo. Dye was then added to enhance the color.

1955 Ansel Adams

1955 Ansel Adams

1955 Ansel Adams

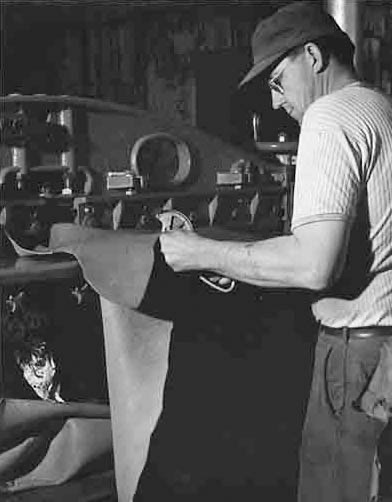

Red McCafferty and a co-worker work with a "splitter" to separate the hide structure into two distinct layers. Splitting the leather into a thinner, more pliable form increased its markets.

1955 Ansel Adams

Split leather was used for making wallets, purses, briefcases and shoes.

1955 Ansel Adams

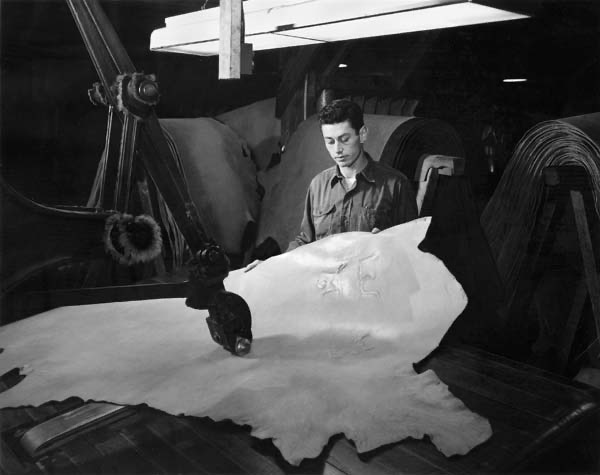

Joe Bellas, plant superintendent at the Salz Tannery during the 1950’s, holds the finished leather product. Bellas was Yugoslavian, and according to the Lezin family, "tough and fair”.

1955 Ansel Adams

Joe holds the finished product. This Ansel Adams photograph was part of a series documenting in 1955 each step of leather tanning.

Salz employees Chuck Anstead and Joe Bellas work with a Sheridan Press.

A stack of sides on a "horse." Horses were used at Salz to move sides of leather around the tannery until the company closed in 2001.

1955 Ansel Adams

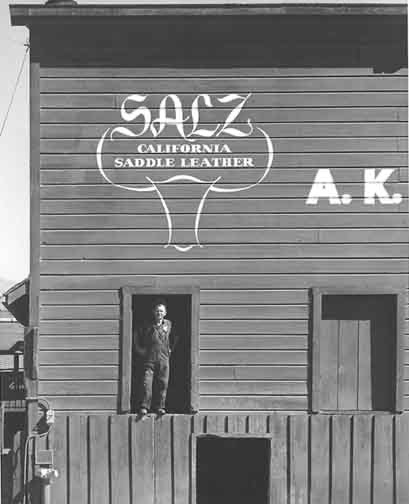

The front of the historic Salz Leathers building remained unchanged for over 140 years. The lettering was more recent. It read in full, "A.K. Salz Company" and featured the company logo for "Salz California Saddle Leather.” An employee stood in an upper window. The tannery was located along the San Lorenzo River on River Street/Highway 9, just north of Highway 1.

1955 Ansel Adams

Vegetable tanned - or tanoak - leather was hung until ready for shipping. Vegetable-tanned leather dried naturally over a period of days. Salz Tannery switched to a chrome process about 1961. The chrome process made a softer tannage, more suitable for footwear and garments. Chrome tanned leather could be dried in a matter of hours. Because it was faster, it was more commercial.

1955 Ansel Adams

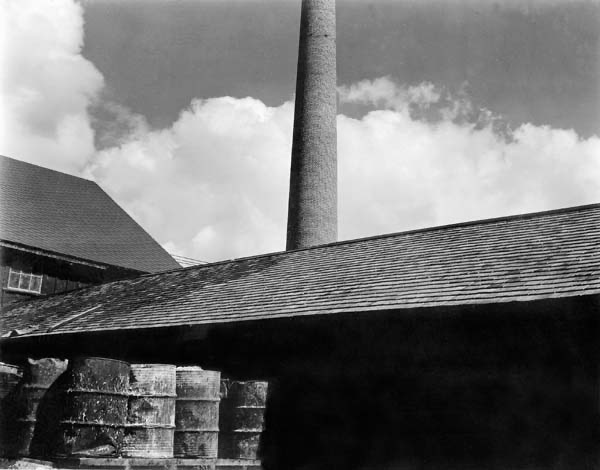

The historic Salz smokestack dated back to the beginnings of the tannery in the 1890's. It fell during the Loma Prieta Earthquake of 1989. Salz staff thought that it had killed an employee who was working in the vicinity when it fell, but he was found at home after the smoke cleared. Though unused at that time for many years, the smokestack was once a landmark for ships arriving in Santa Cruz. Noted photographer Brett Weston took this photo in the mid-1950s.

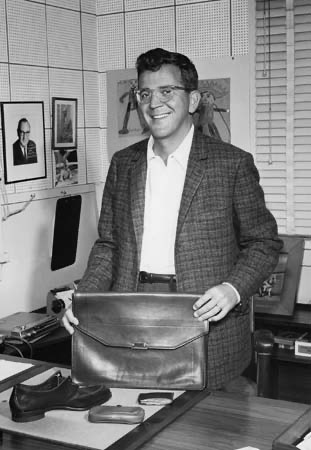

Salz president Norman Lezin graduated from Reed College and originally wanted to pursue a career as a government worker. His marriage to Ansley Salz's daughter Margaret brought him to Santa Cruz. He fell in love with the business and decided to devote himself to making fine leather. Besides running the tannery, he served as mayor of Santa Cruz and port commissioner. He was also instrumental in establishing Delta High School.

Norman succeeded his father-in-law Ansley Salz, founder and president of the company from 1929 to 1947. Norman Lezin served as president from 1947 until 1990. His son Jeremy Salz Lezin followed him as president from 1990 until 2001. Geoff Eisenberg, the first non-family president, then served until the plant closed in September of 2001.

1955 Vester Dick

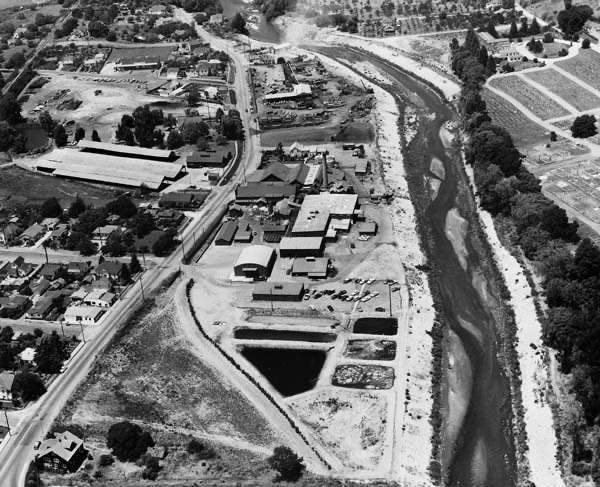

This aerial photograph of Salz Tannery was taken in the early 1950s, possibly by Vester Dick. River Street/Highway 9 is on the left and the San Lorenzo River is on the right.

1950s

This photo of the Salz Tannery lunchroom was taken sometime during the mid-1950s. Salz was one of the very few companies in the '50s and early '60s that hired African Americans. Helen Salz, Ansley's wife, co-founded the ACLU in San Francisco. In the 1950s the Salz workforce numbered about 60. In the '70s that grew to as many as 350. At the end, in 2001, there were approximately 100 employees.

1955 Vester Dick

Salz sales manager Howard Halper presented Miss California with a leather gift at the tannery. Salz Tannery gave a leather purse to each contestant in the Miss California pageant, then held in Santa Cruz. Lee Meriweather toured the plant during the pageant.

1950s Vester Dick

This Salz Tannery greeting card featured a product display that included a saddle, personal leather goods and luggage. Salz California Saddle Leather™ was distributed nationwide with an agent in Mexico as well. In later years Salz sold worldwide, with as many as eight agents. During their last ten years in business their market shifted predominantly to Asia and more specifically to China.

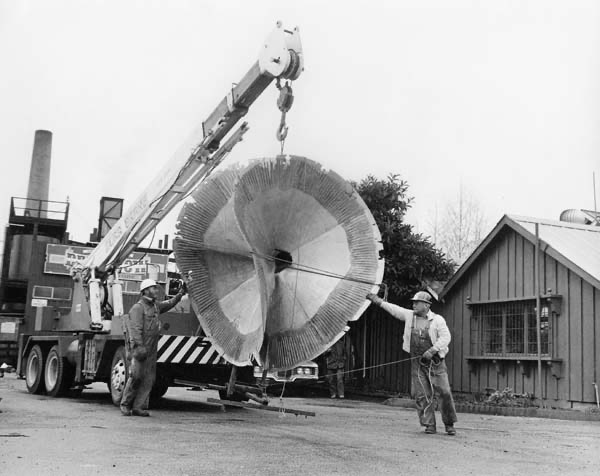

Santa Cruz artist Gene Flores designed a sculpture for Salz Tannery that was both beautiful and functional. Salz Tannery required a cooling tower for a particular piece of equipment. Norman Lezin decided that one of Gene Flores' fountain sculptures would achieve the same objective. It was forged from pie-shaped plates of white bronze, which were poured in sand and then bent with a large brake. Gene Flores worked out of his home on Redwood Drive off Branciforte Drive. He created a significant work of art for $5,000.

1975

The installation of the Salz fountain in 1975 required an enormous crane to move the sculpture from River Street down into the courtyard. Its placement was further complicated by the presence of a mature oak tree that once filled in the courtyard between the offices and processing buildings.

1975

The Salz sculpture was hoisted by crane and paused on River Street prior to its installation in the tannery courtyard.

1975

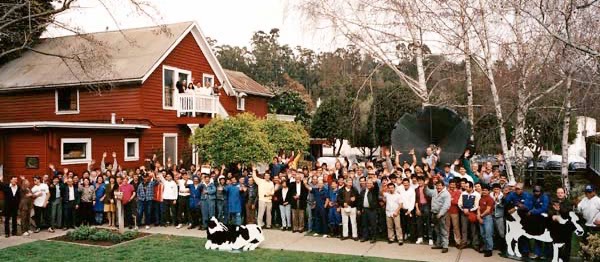

Salz Tannery employed about 185 people in 1985. Though staff from every department was represented in this group photo, there were usually only 60-70% of the staff present at any given time. Whimsical cow cutouts were part of the courtyard scenery. Gene Flores’ sculpture can be seen at centre-right. The tannery was identifiable by the barn red color of its buildings.

1985 Jeremy Lezin

Aerial photograph of the Salz Tannery sometime in the 1980s. River Street/Highway 9 and the Tannery are in the foreground and the growth of trees marks the path of the San Lorenzo River.

Jeremy Lezin

About 130 people worked for Salz Tannery when this photo was taken in 1998. The Lezins took group photographs every 5-10 years for the benefit of the employees - a tradition begun at the turn of the century.

Norman Lezin, chairman of Salz Leathers Inc., walks through the company's River Street plant Friday, hours after the announcement that the 145-year-old company would cease operations.

August, 2001 Schmuel Thaler/Sentinel

The Salz Leathers sign includes the logo as well as the phrase “ NATURAL LEATHER SINCE 1861". The buildings were painted a distinctive barn-red and were a landmark along the River Street/Highway 9 corridor.

Shmuel Thaler/Sentinel

Jeremy Lezin, right, became the new president of Salz Leathers. His father, Norman, left, remained chairman and chief executive officer.

February, 1992 Bill Lovejoy/Sentinel

Stan Blackburn, a 32-year Salz Tannery employee, hauls hides through the plant.

August, 2001 Shmuel Thaler/Sentinel

Salz Leathers Folds Up Shop: Landmark Business to Close this Year

Santa Cruz Sentinel August 4, 2001

Ansel Adams Photographs of the Salz Tannery - 1955

Salz Leathers History A timeline

Berkeley Manasse Block Tannery

Recollections of Manasse Block Tannery

California Historical Tannery Archive

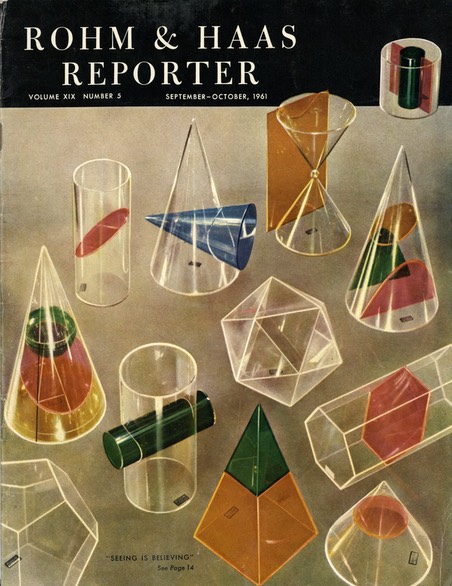

Article excerpted & edited from the 1955 trade publication The Rohm & Haas Reporter

The West Coast tanning firm of A. K. Salz Company, Santa Cruz, California, developed to a high degree of perfection the technique of tanning and finishing leather with its natural grain markings. The company even has a trademarked name for the leather--California Saddle Leather™. The name is not particularly descriptive of the usual application for the leather, for more California Saddle Leather™ is used in the manufacture of luggage, handbags and personal leather goods than in the production of saddles, but the leather has a soft, mellow luster that is reminiscent of a cowboy's well-worn saddle.

The A. K. Salz tannery has been making leather in its present location for a long time. The first hides were "put down" in the tan vats in 1861, only eleven years after California was admitted as the thirty-first state of the union. Then, as now, the chief tanning material was the bark of the Lithocarpus Densiflora, an unusual species of oak which grows almost exclusively in the Coastal Range of Northern California.

The tanning process, from start to finish, represents a combination of techniques - some almost as old as leather itself, and others that are the result of modern research in the science of leather-making. It is a slow, painstaking process, starting in the old beamhouse where the hides are placed in vats for unhairing. Many of these vats are as old as the tannery, and the hides are still moved from vat to vat by the original method of drawing the packs with ropes. The unhairing process itself, however, is strictly up-to-date. The action of the conventional lime and sodium sulfide unhairing bath is improved through the use of dimethylamine sulfate, the first of a number of leather chemicals from Rohm & Haas Company which have application in the Salz tannery. The dimethylamine compound is an effective aid in the unhairing process, loosening the hair efficiently and helping to produce a full, close-fibered leather.

When the hair is loosened, the hides are passed through unhairing machines where dull, rotating knives remove most of the hair. The machine action is followed by a hand operation known as scudding or hand beaming. The moist, flabby hides are thrown over a curved block, or beam, somewhat resembling th e shape of the animal's body, and men, wielding vicious-looking, two handled knives, work over every inch of the hide to remove any hair the machines may have missed. This highly-skilled process removes the remaining follicles, or scud, thus cleaning the pores and aiding in the production of a leather of pleasing color and texture.

Next comes bating and here another Rohm & Haas product, Oropon, has application. The use of Oropon, prepared enzymatic bate, is well-established in the beamhouses of tanneries throughout much of the world. Probably no other trade-marked material is more universally employed in the leather-making process. This product consists of a standardized mixture of proteolytic enzymes and deliming salts, and is available in various grades, making it suitable for use in the production of all types of leather, from the heaviest cowhides to the lightest kips and skivers. The bate removes excess lime and unwanted protein materials, smoothing the grain and leaving it in proper condition to receive the tan liquor, the next step in the tanning process at Salz.

Redwood Tanning Vats

In the Salz tannery there are about one hundred tanning vats, all made of redwood from the forests around Santa Cruz. These vats apparently never wear out, for those which were built when the company began operations in 1861 are still in constant use and are in perfect condition. The wood does not corrode and has no contaminating effect on the tan liquors.

Redwood also serves as "piping" in some applications in the tannery. Hollow, redwood logs bring the tan liquors from the leaching tanks, where they are extracted from the ground up California Oak bark to the tanning vats. These log pipes, as old as the tannery, are as sound as if they were made of the most modern, corrosion-resistant materials.

Unusual Tan

The Lithocarpus, or California Oak, bark tanning liquor produces a leather of golden russet color that is not readily obtained with any other tanning material. At the same time it imparts strength and pliancy to the fibers of the hide, required in a top quality leather such as California Saddle Leather. The hides remain in the tanning vats for weeks as they slowly absorb the tannins and oak sugars from the tan liquor. Nothing is done to hurry this process, for quality rather than quantity is the object of the skilled tanners at Salz Company.

After tanning, the sides are sliced to facilitate handling in subsequent operations. Only the durable top grain is sold as California Saddle Leather. The splits below the top grain are finished and sold to manufacturers who desire a less expensive leather.

Fat-liquoring

The basic properties of the leather are determined by the work in the beamhouse and the tanning processes, but the operations which follow tanning also play a part in the characteristics of the product. The first of these steps is oiling, or fat-liquoring--an operation which restores the natural oils to the hides. The oils lubricate the fibers, insuring strength and flexibility in the finished product.

Drying and Glazing

Next comes drying, with the leather stretched out and tacked to boards. Here again the operation is a slow, painstaking process, so that the leather will dry evenly all the way through, without any "case-hardening" effect on the outside surfaces.

When the sides are thoroughly dry, they are ready for the final finishing operations. No pigmented fillers or paint finishes are used on California Saddle Leather, for these would obscure the natural grain pattern which Salz is seeking to emphasize. A clear, aqueous finish is commonly applied to protect the grain, and the surface is then polished by the glazing jack. This is a power-driven quartz roll which operates like a giant arm to rub the leather to a high polish as the operator manipulates the side beneath it. After glazing, the side is split once more--this time to the exact thickness specified by the buyer.

Plating

Before the final step of plating, an additional clear protective finish may be applied if the end use of the leather requires it. For this finish two products from the Rohm& Haas line of leather finishes may have application--Primal, acrylic base coat, and Orthoclear, transparent nitrocellulose lacquer top coat. Then the leather is plated by pressing between the smooth, hot platens of a huge press which exerts a total force of some three hundred tons against the leather. This compresses and smooths the grain and produces the gleaming, burnished surface which is characteristic of California Saddle Leather.

The story of the A. K. Salz tannery is primarily a story of California Saddle Leather in the natural russet color, for it is in the production of this distinctive leather that the company takes special pride. A visitor to the plant, however, will see some sides of this fine, top-grain leather finished in rich reds, gleaming greens, and other colors. These brilliant aniline colors are highly popular today, and Salz produces a limited quantity of carefully finished leather for this special market.

Family of Craftsmen

Norman Lezin describes the employees of his company as "a family of fine craftsmen who take justifiable pride in the results of their handiwork." It is certainly true that in this period of mass production and standardization, it is unusual to find an industrial organization where the handicraft techniques of a bygone era are as much in evidence as they are at Salz. With the passing years, new buildings have been added to the plant and modern tanning machinery contribute to improved quality in the product, but the tanning process still follows the traditional technique developed by the founders of the firm.

Unique Merchandising

California Saddle Leather-- "the leather with the friendly feel" --is unusual in its production and distinctive in its appearance. It is also unique in its merchandising, for --although A. K. Salz Company produces only leather and makes no finished products-- the firm advertises in national magazines which reach the consumer market as well as in the more conventional trade publications. The company feels that through this means, it can contribute to the centuries-old tradition that fine leather, with its "personality marks" treated as virtues rather than as blemishes, is a possession to be cherished.

Thanks to Photographer Jeremy Lezin and the Lezin family who have allowed the Santa Cruz Library to display images on their Website. The images remain the property of the Lezin family. They may not be downloaded or reproduced in any way without the expressed, written permission of the Lezin family and the Ansel Adams Trust.

Return to California Historical Tannery Archive

Tanning methods and the danger of using chromium-tanned leathers

Begun January 2016