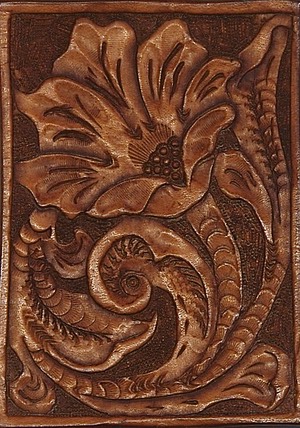

Leathersmithe sandals are made of vegetable-tanned bridle cowhide and require special care in order to assure their long life. Hang your sandals up off the floor during the winter in a dry, temperate location to avoid mold. They have been prepared with saddle soap and dubbin rubbed into all surfaces three times during their construction and final fitting. This is necessary because the traditional stabilizing tanning process that makes the leather malleable enough to conform to your foot's complex curves has removed fats and liquors from the hide that you must periodically replace. You can do this only with saddle soap and dubbin. Never use "mink oil"; it will saturate and weaken the leather.

Most of the leather you'll encounter in this era is much more rapidly, cheaply, chrome-tanned, and while it is stable and doesn't require the use of saddle soap and dubbin, it will never have the rich, gracefully-aging colour nor accept an edge-burnish like bridle-quality oak-tanned cowhide. As you break-in your sandals the straps & insole mold to your feet and provide a custom-fit as no other material can.

Use a piece of coarse cloth (old denim, linen, or a 1” round horsehair shoe brush) to make a light lather with warm water in the saddle soap tin. Rub this foamy lather over and into every surface on the top and edges of your sandals, especially transition points. Straps should be saddle-soaped and pulled back & forth in their channels, to loosen and clean them. Slots for the straps are tight but will loosen with age. The single long 3/8" strap will stretch, as will the broad arch strap, over the life of the sandals.

When you

are done, use a brush or cloth to rub off surplus foam and allow the

sandals to dry for 15 minutes. Then work dubbin into all the

surfaces and the straps until there isn't any residue.

You can walk

around in the sandals until they are dry (the quickest way to break

in new sandals) or allow them to dry for a few hours before wearing

them. While breaking in your sandals: don't tighten your straps more

than I do at your fitting or you will suffer needlessly. They will

require a week or two of intermittent wear (walking in them) in order

to fully break in. Some customers break them in the first day.

Why do I use vegetable-tanned cowhide if it requires (at least) attention after every winter in storage? It's because that long, pit-tanning stabilizes the hides while allowing them to be stuffed (when I build the sandals) with saddle soap and neatsfoot oil, preparing them to be formed by the complex shape and motion of a walking foot. The shoe and boot industry use chrome-tanned cowhide and builds over forms (lasts) which leaves nothing to chance: if a size 9 fits you, don't expect it to change very much over the life of the footwear. Nor to age gracefully as oak-tanned leathers do.

Cromium-tanned leather wouldn't suit your LotR sandal design with its continually-adjustable straps nor the wet-formed arch strap. Your vegetable-tanned cowhide sandals will conform more and more to your feet over their long lifespan.

Your ten year guarantee for fit and

finish requires that you periodically clean, saddle-soap and apply

dubbin to your sandals. Rinse with fresh water if you step into a bog or wear them into

the ocean. I'll replace or refit any straps that break or stretch

(and leather always stretches over time). I can replace your half-soles and heels at your expense ($55 & $45), but if they are

replaced by someone else, your guarantee may be voided.

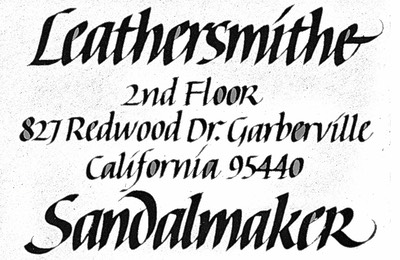

Repairs, Soles & Heels Replacement

1010 Cook Street Victoria 1978

Bags and Pouches

Use saddle soap and dubbin on all surfaces and welt seams in order to restore drying calf, latigo and shoe leathers used for Leathersmithe saddle-stitched bags and pouches. Your ten year guarantee covers stretched, broken straps & separations in the seams. I'll restore them to usable condition.

Dubbin

Fun to watch. But...

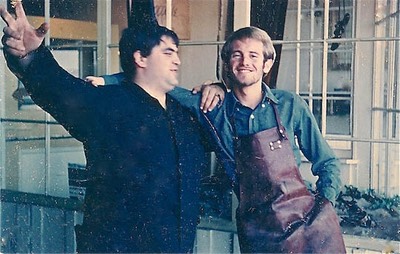

The appeal of a substance with magical properties to enhance and preserve leather began for me when I was 14 and started my leather career. I bought leather and tools from Tandy Corporation which took over Radio Shack in 1962 leaving few Tandy stores in North America. Somehow one survived and was still in business near Bastion Square when I opened "1010 Cook Street" in 1976. I had opened up supply lines from a South San Francisco tannery and two shoe-findings wholesalers in San Francisco, and continued to import leather and buy dyes, saddle soap, buckles, etc. when I visited the Bay Area.

S H Frank in Portland and Seattle were shorter trips with friends I could visit in both states, but only a store in San Francisco remains. I don't cross the line anymore so I depend upon a Burnaby source for shoe finding and soling materials.

When I first escaped the draft and settled in Kitsilano, opening the Psychedelic store with two friends, I made sandals in the front and used the dim room at the back of the building where there was an ancient oil stove which heated the front sales area (not very well). It was there that I perfected what came to be called "bouillabaisse" by the few leatherworkers in Vancouver. The name came from a large oily spot I got on a new slim-fitting elk jacket I'd made myself for a trip to Seattle in 1970 and an ill-fated dinner at a renowned seafood restaurant where I splashed some soup, yes: bouillabaisse, on the front, and when I returned to my 4th Avenue Kitsilano Vancouver shoppe where I made my own concoction of leather dressing I added other splashes to the jacket from my production of substances on the stove. I tried many combinations of the basic ingredients, by the way.

I gave tins of my perfected mix to the other local leatherworkers and the name stuck.

Once two detectives came into the store when I was in the back, stirring the latest concoction, and there in the near-dark they thought that myths about Kitsilano production of LSD was going on. I gave them the story and somehow convinced them, although it sounded far-fetched. Still does.

Important considerations in designing a leather finishing product: there are many ways that leather is tanned and finished, for many different uses. The mix in this video complemented the boots and gave them an attractive, even colour and shine, but there are many types of tanning, many leather finishes, that require more than the sum of the parts of this fellow's recipe.

I gave up on combining substances and since those innocent, halcyon hippy days, I use old standbys for my last finishing process on most things that I make.

- However, depending upon the age/condition of used leather (like boots, wallets, belts, pouches, bags, sandals) I consider saddle soap to always be the first substance to be used.

- It's made into a foamy cream in the SS can with a horsehair brush or rag, using plenty of water.

- That's applied liberally, allowed to dry, and the residue and dirt lifted by the SS brushed-off with a dry horsehair brush.

- If the leather is new or very dry I mix into the SS tin a tablespoon or two of neatsfoot oil which combines with the lather and is absorbed well.

- Lastly I rub into the edges one of the

commercial dubbins, two of which I have for sale at my Farmers

Market table, and then I burnish edges with antler or wooden

mandrels, use a dedicated brush and my fingers to rub the dubbin

into the rest of the leather, and brush away any residue.

The saddle soap/neatsfoot oil mixture restores fats and liquors removed from the hides during tanning to preserve the leather, and this encourages flexibility of straps and insoles when I build sandals or renovate them.

Natch, the vegetable-tanned bridle cowhide I use for the slim and broad straps and the insoles and edges of sandals receive most of my finishing and restoring attention. You won't encounter the use of this tanning outside of the equestrian world. First-world primitive tanning uses similar substances and procedures.

Rough-out boot leathers, chromium-tanned, are meant to be stable throughout their life, so I use the same process even though they aren't meant to stretch and form-fit past a certain early stage, and they may not be helped by adding more oil of any kind. Similarly, other tannings may require variations on my procedure.

Here is my page on finishing/restoring sandals

As you can see this topic is fertile ground for personal choices based upon experience, and I haven't come across anyone in the leather world with more years of sandalmaking than I, so I speak with some authority.

Your mileage may differ.

"Thanks for all your care and time Davy. I'm wearing my beautiful sandals and they are getting more comfortable with every minute as we become accustomed to each other. I hope we have a long life together. Lets plan on celebrating in 10 years!" 7/2023 LB

The importance of saddle-soaping and dubbin & how to apply them

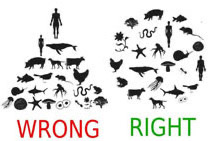

Tanning methods and the danger of using chromium-tanned leathers

Is leather just a by-product of the meat industry?

The entire epidermal layer of your skin turns over every forty-eight days

Halvah

Preferred diet-supplement of sandalmakers around the globe

Begun December 2015